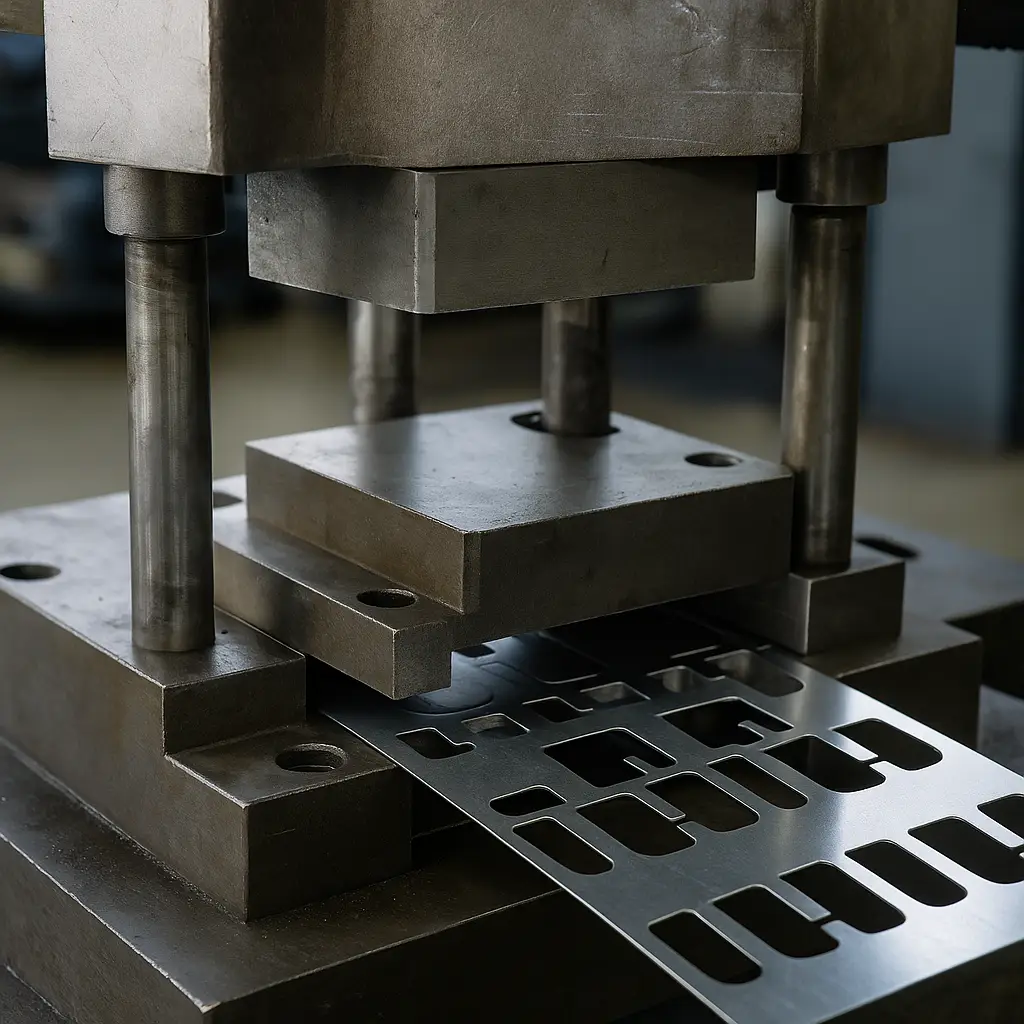

Gib-Guided Press

Tonnage range: 100–1000 tons

Price: $12,000 - $56,000

Our industrial hydraulic press machines are engineered for a wide range of production needs, delivering reliability, precision, and flexibility across key applications:

① Forming & Stamping – High-precision metal and composite molding with consistent repeatability.

② Assembly & Press-Fitting – Closed-loop control ensures defect-free bearing and electronics assembly.

③ Embossing & Surface Texturing – Micron-level accuracy for detailed patterns and logo reproduction.

④ Stretching & Shaping – Ideal for aerospace-grade alloys and high-strength material forming.

⑤ Cutting & Shearing – Multi-material processing with clean edges and fine surface finish.

All systems are CE/SIL3 certified, supported by global service within 48 hours, and available from 10 to 1000 tons to match diverse production requirements.

Focuses on high precision and intelligent control, suitable for scenarios requiring high machining accuracy.

Tonnage range: 100–1000 tons

Price: $12,000 - $56,000

Tonnage range: 0.2–8 tons

Price : $6000 - $38,000

Tonnage range: 75–300 tons

Price : $12,000 - $88,000

Compact and portable design, suitable for laboratory or small-scale production settings.

Tonnage range: 5–50 tons

Price : $3000 - $16,000

Tonnage range: 0.3–2.2 tons

Price : $12,000 - $56,000

Tonnage range: 3–30 tons

Price : $3000 - $18,000

Suitable for various standard pressing needs, offering wide coverage and diverse functions.

Tonnage range: 50–500 tons

Price : $12,000 - $56,000

Tonnage range: 5–100 tons

Price : $6000 - $38,000

Tonnage range: 5–50 tons

Price : $6000 - $38,000

Tonnage range: 100–1000 tons

Price : $12,000 - $56,000

Equipped with a heating function, suitable for plastics, composites, or other heat-processing applications.

Tonnage range: 30–500 tons

Price : $12,000 - $56,000

For sheet metal forming, trimming, and blanking

Recommended: H-frame or 4-post, 100–500 tons

For cups, cans, kitchenware, and auto body parts

Recommended: 200–1000 tons, 4-post with cushion

For composites, powder metallurgy, plastics, and rubber parts

Recommended: 200–800 tons, heated platen press

For motor shafts, bearings, electronics assembly

Recommended: C-frame or servo-hydraulic, 10–200 tons

For decorative panels, logos, and precision surface finishing

Recommended: 50–200 tons, C-frame with precision control

For aerospace alloys, beams, and structural parts

Recommended: H-frame, 100–500 tons

For multi-material cutting, clean edges, and high surface finish

Recommended: 50–300 tons with guided tooling

For metal powder, ceramics, and magnetic parts

Recommended: 50–500 tons with closed-loop force control

Our hydraulic presses are available from 10 tons up to 1000 tons, with customizable table sizes and stroke lengths to fit specific production needs. Standard configurations cover stamping, forming, molding, and assembly processes. We also provide tailor-made solutions for non-standard tonnage or special tooling requirements.

Yes. Each press can be customized by tonnage, table size, stroke, speed, and control system. Optional features include servo-hydraulic drives, heated platens, cushions for deep drawing, force-displacement monitoring, and automated feeding systems. Our engineering team provides one-to-one consultation to ensure the press matches your process and tooling requirements.

Standard models: 30–55 working days

Customized models: 60–90 working days

We keep certain core configurations in production for faster delivery, while complex customized presses require additional engineering and testing before shipment.

All machines are designed and built to comply with CE requirements and international safety regulations (e.g., ANSI B11.2). Electrical and control systems support EN/IEC standards, and we can provide test certificates, quality reports, and third-party inspection as required.

We offer a 3-year full machine warranty and lifetime technical support. Our overseas localized service teams (Europe/USA/Southeast Asia) provide 24/7 multilingual assistance in EN/DE/JP/CN. Spare parts, remote diagnostics, and on-site service are available to ensure minimum downtime.

Yes. Every press is shipped with a complete set of technical manuals, electrical diagrams, and maintenance guides. We provide on-site installation and commissioning or remote guidance, depending on your location and project scale. Packaging is export-standard with IP67 protection, and we cover EXW/FOB/CIF/DDP terms with hazardous material packaging if required.