Hydraulic presses have revolutionized the manufacturing industry, facilitating processes that require extreme force and precision. These machines, hailing from the heart of the Industrial Revolution, are now integral to countless operations, from shaping metal parts to forming rubber components. The hydraulic press machine, ubiquitous in small businesses and large industries alike, has a cost that can vary widely depending on several factors. This article aims to guide you through the intricacies of hydraulic press machine pricing, features, and benefits, answering questions like “how much is a hydraulic press?” and delving into the price of presses with different tonnage.

The Hydraulic Press and its Role

Invented by Joseph Bramah in the 18th century, the first hydraulic press laid the foundation for modern industrial presses. The principle of Pascal’s Law – that pressure change occurs uniformly throughout a fluid – allows these machines to exert vast amounts of force. This force, applied via hydraulic cylinders, is capable of bending, shaping, and stamping different materials, making hydraulic presses the backbone of various industries, including metal fabrication, automotive, aerospace, agriculture, and more.

Small businesses and larger industrial companies alike benefit immensely from the precision and power that hydraulic presses bring to their operations. Whether it’s a farm needing to shape equipment parts or a workshop creating custom metal components, the ability to manipulate materials with such control and force is invaluable.

Components and Features of a Hydraulic Press

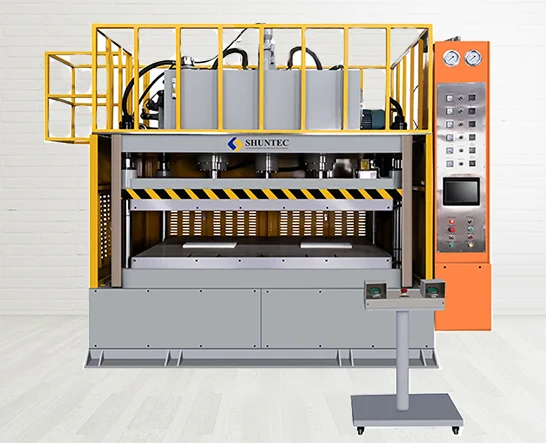

A hydraulic press machine is composed of several key components, each playing a crucial role in its function. The motor powers the pump, which circulates the hydraulic fluid through the system under high pressure. This fluid acts upon the hydraulic cylinders, creating force that is transmitted to the press plates. The control mechanisms allow the operator to accurately adjust the force and stroke length, while the frame – often an H frame, bench mounted, or floor mounted design – provides the necessary stability.

There are different types of hydraulic presses available in the market. A shop press, commonly used in automotive repair and small workshops, is excellent for tasks such as removing and installing bearings, bushings, gears, and ball joints. Forging presses are used in the forging process to shape metal using localized compressive forces, while a press machine could refer to any machine that uses pressure to generate a force.

The capacity of a press, measured in tons, refers to the maximum amount of force that the press can exert. The weight, motor capacity, and build quality are other significant factors that influence the performance and durability of a press. The precision and control provided by a hydraulic press are critical, especially for jobs requiring high levels of accuracy.

The Cost of a Hydraulic Press

The cost of a hydraulic press can vary greatly, influenced by factors such as capacity, size, brand, and additional features. Here’s a general idea of what you can expect to pay for different tonnage hydraulic presses:

- A 100-ton hydraulic press could cost anywhere from $10,000 to $30,000. These presses are commonly used for tasks like stamping, straightening, and assembly work in smaller industries.

- A 150-ton hydraulic press often costs between $20,000 and $50,000. They are ideal for heavier-duty work in larger manufacturing operations.

- A 200-ton press machine might range from $30,000 to $60,000. These are robust machines capable of heavy-duty industrial work.

- A 250-ton hydraulic press typically costs between $40,000 and $70,000. They are used in industries requiring a high degree of force for operations like deep-drawing, molding, and die-cutting.

- A 300-ton hydraulic press usually falls in the price range of $50,000 to $80,000. These machines are well-suited for heavy-duty applications in larger industries, including automotive and aerospace.

- A 400-ton hydraulic press can range from $60,000 to $100,000. Its high capacity makes it ideal for tasks requiring extreme force, such as forming large metal parts or components.

- A 500-ton hydraulic press might cost between $80,000 and $150,000. These machines are frequently found in heavy industries like shipbuilding and large-scale construction.

- The price of a 5000-ton hydraulic press could run into several million dollars. These colossal machines are used for ultra-heavy-duty tasks, like shaping airplane parts or large ship components.

Please note, these prices are estimates and can vary based on the specific make, model, and additional features of the hydraulic press.

Choosing the Right Hydraulic Press for Your Needs

Choosing the right hydraulic press depends on several factors. Consider the intended job and materials: are you stamping metal, forming rubber, or shaping wood? The nature of the material and the complexity of the shaping, bending, or stamping process will influence the type and capacity of press you need.

For small businesses, it’s crucial to balance cost with functionality. A manual press might be a more affordable option, but automatic hydraulic presses, while more expensive, offer greater precision and efficiency.

The press plate, ram, and hydraulic cylinder are among the most significant parts of the press machine. The press plate’s size and material will affect the types of jobs the machine can handle, while the hydraulic cylinder’s capacity will determine the amount of force the machine can exert. The ram – the part of the machine that applies pressure to the material – must be durable and of high quality to withstand repetitive force.

The choice of different materials plays a crucial role in shaping and stamping objects. For example, metal can withstand higher pressure than rubber or wood, so the type of material you intend to work with may influence the pressure and tonnage you need.

Maintenance and Repair

Regular maintenance of a hydraulic press is vital to ensure its longevity and optimal performance. Regular checks and timely replacement of hydraulic fluid, seals, and bearings can prevent many common hydraulic press issues. Additionally, ensuring the load does not exceed the machine’s capacity will protect the pump and hydraulic cylinders from excessive wear.

While routine maintenance can prevent many problems, hydraulic presses, like all machines, can require repairs. Common issues include seal leaks, valve malfunctions, and pump failures. These repairs, if not addressed promptly, can lead to more serious damage and potential safety hazards, and therefore, add to the overall cost of owning and operating a hydraulic press.

Purchasing a Hydraulic Press

When purchasing a hydraulic press, consider the total cost, including shipping and installation. Some companies include these in the listed price, while others charge additional fees. It’s also crucial to factor in the cost of potential modifications needed to accommodate the machine, such as reinforced flooring or additional space.

There are many reputable companies that manufacture hydraulic presses, each offering different models with various features. Researching and comparing these options will help ensure you purchase a press that best suits your needs and budget.

Having a complete shop press in your workshop or farm can be a game-changer. Whether you need to bend metal for a repair job, shape rubber for a specific part, or stamp a design onto a piece of wood, a hydraulic press can make the job quicker, easier, and more precise.

ConclusionIn

conclusion, the cost of a hydraulic press can vary greatly depending on its tonnage, brand, and additional features. Regardless of the price tag, investing in a hydraulic press can be a game-changer for businesses large and small, providing an ability to shape and manipulate materials with a precision and force that other machines can’t match.

It’s essential, however, to consider more than just the initial purchase price. Regular maintenance and potential repair costs can add to the total cost of ownership over time. Regular checks of key components such as bearings, hydraulic fluid, load capacity, and others can help extend the machine’s life and keep it running efficiently.

When choosing a hydraulic press, it’s crucial to consider not only the intended job and materials to be worked on but also the space available and any necessary modifications to your premises. For small businesses, a manual press might be a more cost-effective choice, but if precision and speed are paramount, an automatic hydraulic press could be a wise investment.

We offer a wide variety of hydraulic presses, with capacities ranging from a few tons to several thousand. Detailed specifications, user reviews, and pricing information are available on our website, helping you make an informed decision.

Lastly, remember that a hydraulic press is more than just a tool—it’s an investment in your business’s future. A well-chosen hydraulic press can significantly improve productivity, reduce labor costs, and enable you to take on more complex jobs.

In essence, while the question of “how much do hydraulic press cost?” can be answered with a range of figures, the true cost — or indeed, value — of a hydraulic press lies in how well it meets your specific needs. And, equipped with the knowledge from this article, you are now well-prepared to make that assessment.