Hydraulic fluids play a critical role in the smooth operation of hydraulic systems, widely used in industries ranging from manufacturing to construction. These fluids are responsible for transferring energy, lubricating components, and helping to dissipate heat. However, with their essential role comes a significant safety consideration: the flammability of hydraulic fluids.

In this article, we’ll dive deep into the flammability of hydraulic fluids, exploring the different types of fluids, their ignition points, and the factors that influence their flammability. Whether you’re working in an industrial setting or just seeking a better understanding of hydraulic systems, this guide will provide valuable insights into the fire risks and necessary precautions when handling hydraulic fluids.

What is Hydraulic Fluid?

Hydraulic fluid is a specially designed liquid used in hydraulic systems to transfer force and energy. These systems are crucial in industries like manufacturing, construction, and aerospace, powering machinery such as excavators, presses, and aircraft controls. Beyond energy transmission, hydraulic fluids also help with lubrication, cooling, and reducing wear on system components.

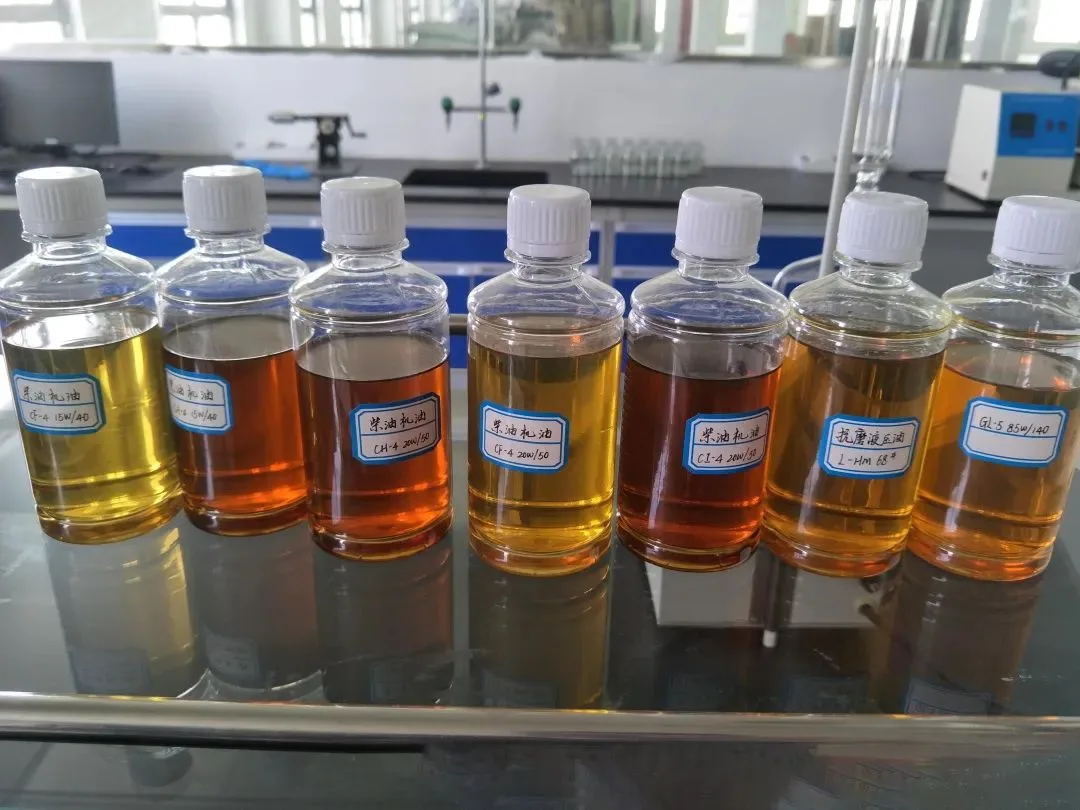

There are four primary types of hydraulic fluids:

- Mineral Oil-Based Hydraulic Fluid: The most common and cost-effective type, derived from refined petroleum. Mineral oil-based fluids are stable under normal conditions but are highly flammable.

- Synthetic Hydraulic Fluid: Made from chemical compounds, synthetic fluids are engineered to offer better thermal stability and oxidation resistance. They tend to have a lower risk of flammability compared to mineral oils and perform well in extreme temperatures.

- Water-Based Hydraulic Fluid: These include water-glycol mixtures that are less flammable due to their high water content. However, they are less effective in high-pressure, high-temperature environments and can be corrosive.

- Biodegradable Hydraulic Fluid: Made from vegetable oils or synthetic esters, biodegradable fluids are an environmentally friendly alternative. They break down naturally when exposed to the environment, reducing ecological impact in case of leaks.

For a more detailed, check out our comprehensive Hydraulic Fluid Guide.

Flammability of Hydraulic Fluid

The flammability of hydraulic fluid is a crucial safety consideration for industries that rely on hydraulic systems. Since hydraulic fluids are often exposed to high temperatures and pressurized environments, understanding their fire risks is essential for implementing effective safety protocols.

- Mineral Oil-Based Hydraulic Fluids: These fluids are highly flammable. Derived from petroleum, they tend to catch fire easily when exposed to heat or open flames. The flashpoint – the lowest temperature at which the fluid releases enough vapor to ignite – is typically around 200°F (93°C) or higher for mineral oils. This means that even in environments where temperatures are not excessively high, mineral oil-based hydraulic fluids can pose a significant fire hazard.

- Synthetic Hydraulic Fluids: While generally less flammable than mineral oils, synthetic fluids still carry fire risks. They are formulated to withstand higher temperatures and to have improved thermal stability, which makes them more resistant to ignition. However, their flammability can still vary depending on the specific formulation and the conditions in which they are used. For example, phosphate esters and other synthetic fluids used in aviation systems are designed to be fire-resistant but can still catch fire under extreme conditions.

- Water-Based Hydraulic Fluids: These fluids, including water-glycol mixtures, have a much lower risk of combustion due to their high water content. The water component acts as a natural fire retardant, making these fluids much safer in terms of flammability. However, they are less effective in extreme temperature conditions and are prone to corrosion over time. While they are significantly less flammable than mineral oil-based fluids, they are not completely immune to fire hazards, especially when water content decreases or when exposed to high heat over prolonged periods.

- Biodegradable Hydraulic Fluids: Typically made from vegetable oils or synthetic esters, biodegradable hydraulic fluids combine environmental benefits with relatively low flammability. They are more resistant to ignition compared to mineral oils but can still burn if exposed to high temperatures or direct flame. Their flammability varies depending on the specific formulation and whether they are water-in-oil or oil-in-water emulsions.

While the flammability of hydraulic fluids depends on their type and formulation, all hydraulic fluids have the potential to catch fire under the right conditions. It’s crucial to follow proper safety protocols, ensure adequate fire suppression systems, and monitor temperature levels in systems that use flammable hydraulic fluids.

Flashpoint and Firepoint of Hydraulic Fluids

Understanding the fire characteristics of different hydraulic fluids is crucial for selecting the right fluid for specific applications and minimizing fire risks in hydraulic systems. The fire resistance of hydraulic fluids can vary significantly depending on their chemical composition and intended use. Below is a comparison of the fire characteristics of the most common hydraulic fluid types: Mineral Oil-Based, Synthetic, Water-Based, and Biodegradable hydraulic fluids.

Mineral Oil-Based Hydraulic Fluids

- Flammability: Mineral oil-based hydraulic fluids are highly flammable and are considered a significant fire hazard. These fluids have relatively low flashpoints, typically between 200-250°F (93-121°C), which makes them prone to igniting at lower temperatures compared to other fluid types.

- Firepoint: The firepoint of mineral oil-based fluids ranges from 400-500°F (204-260°C). Once ignited, these fluids can continue to burn unless fire suppression measures are applied.

- Applications: Widely used in industrial applications due to their low cost and availability. However, their fire risk is high, especially in systems where there are elevated temperatures or open flames.

- Precautions: To manage fire risk, regular fluid monitoring, proper fluid containment, and temperature control are essential. Use of flame arrestors or explosion-proof equipment is recommended in high-risk environments.

Synthetic Hydraulic Fluids

- Flammability: Synthetic hydraulic fluids are generally more fire-resistant than mineral oils. Their flammability depends on the specific formulation, but they typically have a higher flashpoint, often ranging from 300-450°F (149-232°C).

- Firepoint: The firepoint of synthetic fluids is higher than that of mineral oils, typically around 500-600°F (260-316°C). These fluids are designed to perform well in high-temperature environments without igniting easily.

- Applications: Commonly used in industries that require high performance and safety, such as aviation and aerospace, where fire safety is a critical concern. Some synthetic fluids are specially formulated for fire resistance.

- Precautions: Although they are more fire-resistant, synthetic fluids can still catch fire under extreme conditions. Routine system maintenance and temperature control are still critical to preventing fires.

Water-Based Hydraulic Fluids

- Flammability: Water-based hydraulic fluids, such as water-glycol mixtures, have the lowest flammability among the common hydraulic fluids. The high water content (typically 30-50%) makes them much less likely to ignite. However, they are still not entirely fireproof and may burn under extreme conditions.

- Flashpoint: Water-based fluids typically have a flashpoint of 300-400°F (149-204°C), but their firepoint is higher, around 450-550°F (232-288°C). The high water content helps in reducing the overall fire risk.

- Applications: Often used in applications where fire risk is high, such as in mining and steel industries, but they are less effective in extreme temperatures or high-pressure systems.

- Precautions: While water-based fluids offer safety advantages, they can cause corrosion and degradation in the system. Proper maintenance to ensure the correct water-to-fluid ratio and regular inspections are necessary to prevent leaks and damage.

Biodegradable Hydraulic Fluids

- Flammability: Biodegradable hydraulic fluids are usually made from vegetable oils or synthetic esters, offering a relatively low fire risk compared to mineral oils. However, they still pose a fire hazard, especially if exposed to high temperatures.

- Flashpoint: The flashpoint of biodegradable fluids generally ranges from 300-450°F (149-232°C), depending on the specific fluid. These fluids tend to be less flammable than mineral oils but still need to be handled with care.

- Firepoint: The firepoint of biodegradable fluids typically falls between 450-600°F (232-316°C), similar to synthetic fluids. Their fire resistance is not as high as water-based fluids, but they provide a good balance of environmental safety and fire resistance.

- Applications: Ideal for environmentally sensitive areas, such as forestry, agriculture, and offshore drilling, where fluid leaks can cause environmental damage. These fluids are a better alternative when environmental sustainability is a priority.

- Precautions: While less flammable than mineral oils, biodegradable fluids still require proper handling, regular system maintenance, and monitoring to ensure safety.

Comparison Table: Fire Characteristics of Common Hydraulic Fluids

| Type of Hydraulic Fluid | Flashpoint | Firepoint | Flammability | Applications | Precautions |

|---|---|---|---|---|---|

| Mineral Oil-Based Hydraulic Fluid | 200-250°F (93-121°C) | 400-500°F (204-260°C) | Highly flammable | Industrial machinery, construction | Temperature control, leak detection, fire suppression |

| Synthetic Hydraulic Fluid | 300-450°F (149-232°C) | 500-600°F (260-316°C) | Less flammable | Aerospace, aviation, high-temperature systems | Maintenance, temperature control, fire-resistant fluids |

| Water-Based Hydraulic Fluid | 300-400°F (149-204°C) | 450-550°F (232-288°C) | Low flammability | Mining, steel industry | Corrosion prevention, proper fluid ratios, regular inspections |

| Biodegradable Hydraulic Fluid | 300-450°F (149-232°C) | 450-600°F (232-316°C) | Lower flammability | Environmentally sensitive applications | Regular monitoring, proper handling, system checks |

Each type of hydraulic fluid has its own fire characteristics, making it essential to choose the right fluid based on specific operational needs and safety concerns. While water-based fluids offer the best fire resistance, synthetic fluids and biodegradable fluids provide a good balance of fire resistance and performance. Mineral oil-based fluids, though cost-effective, present the highest fire risk and require careful management in high-temperature environments. Proper fluid selection, maintenance, and safety protocols are crucial for mitigating fire hazards in hydraulic systems.

Fire Risk Management and Safety Measures

Given the flammability of hydraulic fluids, managing fire risks is a critical component of ensuring the safe operation of hydraulic systems. Effective fire risk management involves a combination of prevention strategies, safety protocols, and proper system maintenance. Here are key safety measures to reduce the risk of fire in environments using hydraulic systems:

Proper Fluid Selection

Choosing the right hydraulic fluid for the operating environment is the first step in fire risk management.

- Flame-Resistant Fluids: In environments where fire risk is high, such as in aerospace or high-pressure industrial systems, using flame-resistant hydraulic fluids – such as phosphate esters or synthetic fluids with fire-resistant properties – is essential.

- Water-Based Fluids: For areas with less extreme temperature or pressure conditions, water-based hydraulic fluids are a safer option due to their lower flammability. However, these fluids should be used carefully, as they are prone to corrosion.

- Biodegradable Fluids: For environmentally conscious operations, biodegradable hydraulic fluids offer a more sustainable option with a lower risk of environmental damage in case of leaks.

Regular System Maintenance

Regular maintenance of hydraulic systems is crucial in preventing fire hazards. Proper inspection and servicing can help identify potential risks before they lead to serious accidents:

- Leak Detection: Regularly inspect hydraulic systems for leaks. Leaked hydraulic fluid, especially when exposed to high temperatures, can quickly become a fire hazard.

- Component Checks: Inspect key components, such as hoses, seals, and pumps, for wear and tear that could lead to friction or overheating, which may increase the risk of fire.

- Temperature Control: Ensure that temperature control mechanisms (such as heat exchangers or cooling systems) are functioning properly to prevent the hydraulic fluid from reaching unsafe temperatures.

Proper Ventilation

In enclosed environments, hydraulic fluid vapors can accumulate and create an explosive atmosphere. Proper ventilation is essential to minimize the concentration of flammable vapors and ensure that any fumes are dissipated before they can ignite.

- Ventilation Systems: Install exhaust or ventilation systems to direct harmful vapors away from heat sources or ignition points.

- Regular Air Quality Monitoring: Conduct regular air quality checks to ensure that flammable vapors are not present at hazardous levels.

Fire Suppression Systems

In high-risk environments, it’s important to have fire suppression systems in place to quickly contain and extinguish fires before they escalate. Some common fire suppression methods include:

- Automatic Sprinkler Systems: These systems can be programmed to activate in the event of a fire, rapidly cooling and suppressing flames.

- Fire Extinguishers: Ensure that appropriate fire extinguishers (such as Class B or C extinguishers for flammable liquids and electrical fires) are readily available and regularly serviced.

- Fire Blankets: For small hydraulic fluid fires, having fire blankets on hand can be an effective way to smother flames quickly.

Training and Awareness

All personnel who work with hydraulic systems should be thoroughly trained in fire safety procedures. This includes understanding the flammability of hydraulic fluids, knowing how to react in case of a fire, and being familiar with the correct fire suppression equipment.

- Fire Safety Drills: Regularly conduct fire drills to ensure that employees know how to respond in the event of a fire. This includes safe evacuation routes and the use of firefighting equipment.

- Fluid Handling Procedures: Educate employees on proper handling and storage of hydraulic fluids to minimize the risk of spills or exposure to heat sources.

Fire-Resistant Barriers and Containment

For systems operating in extremely high-risk environments, consider implementing fire-resistant barriers or secondary containment measures to prevent the spread of fire or hydraulic fluid leaks.

- Containment Pits or Trays: Install trays or pits around hydraulic equipment to contain any potential fluid leaks, preventing them from spreading and igniting.

- Heat Shields: Use heat-resistant shields or barriers around hydraulic components to protect against external heat sources or potential fire hazards.

How to Choose the Right Hydraulic Fluid to Minimize Fire Risk

Choosing the right hydraulic fluid is a critical step in minimizing fire risks in hydraulic systems. The type of fluid you select will directly impact the fire safety of the system, as well as its performance, durability, and environmental impact. Here are the key factors to consider when selecting a hydraulic fluid to reduce fire hazards:

Assess the Operating Environment

The first step in choosing a hydraulic fluid is to assess the operating environment. The conditions under which the hydraulic system will operate – such as temperature, pressure, and exposure to open flames or hot surfaces – play a significant role in determining the best fluid.

- High-Temperature Environments: In applications where the hydraulic system operates at elevated temperatures (such as in heavy machinery or aerospace), consider using synthetic hydraulic fluids or fire-resistant fluids. These fluids have higher flashpoints and are designed to perform better under extreme conditions.

- Flame-Exposure Risks: In environments where the system might be exposed to open flames or sparks (such as in petrochemical plants or industrial plants), fire-resistant fluids like phosphate esters or water-based fluids are preferable.

Evaluate Fluid Fire Resistance

Not all hydraulic fluids are created equal when it comes to fire resistance. The following options provide different levels of fire resistance:

- Water-Based Fluids: These fluids are less flammable due to their high water content, which acts as a natural fire retardant. They are a good choice for low-risk applications where the system is not exposed to extremely high temperatures. However, water-based fluids may cause corrosion and have limited performance in high-pressure, high-temperature environments.

- Synthetic Fluids: These offer a good balance between fire resistance and performance. Fluids like phosphate esters or organophosphate esters are often used in high-risk environments such as aviation, where fire safety is critical. Synthetic fluids are more stable at higher temperatures than mineral oils and are generally more resistant to ignition.

- Biodegradable Fluids: If environmental impact is a concern, biodegradable hydraulic fluids made from vegetable oils or synthetic esters are an option. While they are generally less flammable than mineral oils, they should still be selected with fire risk in mind, particularly for outdoor applications or areas with high fire risk.

Consider System Pressure and Temperature

Hydraulic systems operating under high pressure or temperature conditions require fluids with higher stability and better resistance to thermal breakdown.

- Mineral Oil-Based Fluids: These are generally stable under moderate pressure and temperature but can pose significant fire risks in systems exposed to excessive heat. They are best used in systems with lower pressure or in controlled environments where fire prevention measures are in place.

- Synthetic Fluids: If your system operates in extreme conditions (such as high temperatures or pressures), synthetic hydraulic fluids offer superior performance and reduced fire risks. They are specifically formulated to withstand extreme conditions without compromising safety.

Factor in Environmental Considerations

Environmental concerns play an important role in fluid selection, especially in industries where hydraulic systems are used outdoors or near water sources.

- Biodegradable Fluids: These fluids are ideal for environmentally sensitive areas where spills could cause long-term damage. Biodegradable fluids tend to be less flammable than mineral oils but still provide excellent fire resistance. Choose biodegradable options if sustainability and environmental impact are top priorities.

Cost and Maintenance Considerations

While fire-resistant fluids may come at a higher initial cost, they can potentially save money in the long term by reducing fire risks and improving system safety. Additionally, fluids with higher fire resistance may require less frequent replacement and maintenance, which can be cost-effective for high-use or high-risk applications.

- Mineral Oils: These are often the least expensive but come with a higher risk of fire. They may be suitable for lower-risk, low-cost applications where fire prevention measures are in place.

- Fire-Resistant Fluids: Consider the long-term safety benefits of choosing fire-resistant fluids, especially for systems in hazardous environments or those with high safety standards.

Consult Manufacturer Recommendations

Always consult the manufacturer’s guidelines and recommendations for your specific hydraulic system when selecting a fluid. Manufacturers often provide specific advice on the optimal fluid type based on the equipment’s design and intended use. This ensures the system operates safely and efficiently, while minimizing the risk of fluid-related fires.

Conclusion

In summary, understanding the flammability of hydraulic fluids is crucial for maintaining safety in systems where these fluids are used. The choice of hydraulic fluid – whether mineral oil-based, synthetic, water-based, or biodegradable – plays a significant role in fire risk management. Each fluid type has distinct fire characteristics, with mineral oil-based fluids being the most flammable and water-based fluids offering the lowest risk of combustion.

To minimize fire risks, it’s essential to assess the operating environment, select the appropriate fluid with the right fire resistance properties, and implement regular system maintenance. By doing so, industries can ensure safer, more efficient operations while protecting both personnel and equipment from potential fire hazards.

Choosing the right hydraulic fluid, coupled with effective fire prevention strategies, helps create a safer working environment and extends the life of hydraulic systems.